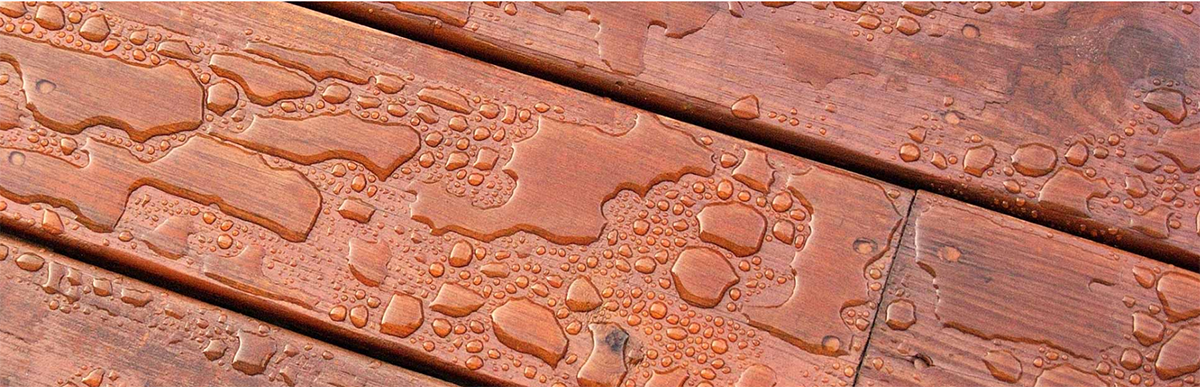

Druri është një material shumë poroz. Kur e përdorni për të ndërtuar struktura ose produkte, duhet të jeni në gjendje të siguroheni që nuk do të kalbet në një periudhë të shkurtër kohore. Për ta bërë këtë, përdorni një shtresë. Megjithatë, në të kaluarën, shumë shtresa kanë qenë problematike sepse lëshojnë kimikate të dëmshme në mjedis. Për të shmangur këtë problem, ne ofrojmë shërbimin e shtresëzimit të tharë me UV për t'ju ofruar një zgjidhje më të mirë.

Çfarë është një shtresë e kuruar me UV?

Një shtresë e tharë me UV nuk do të lëshojë kimikate të dëmshme. Gjithashtu, ajo siguron mbrojtje më të gjatë për drurin. Ky lloj shtrese mund të përdoret për një sërë produktesh, jo vetëm për dru. Mund ta përdorni për metal, xham, printerë, beton, pëlhurë dhe letër. Ekziston edhe shtresë UV për plastikën. Duke përdorur shtresën UV, do të zbuloni se kurseni kohë dhe para. Për më tepër, nëse rishisni produkte, klientët tuaj do të marrin një vlerë më të mirë të përgjithshme, që mund të nënkuptojë besnikëri dhe kthim afatgjatë të biznesit. Nëse keni shqetësime në lidhje me çështjet mjedisore me biznesin tuaj, kalimi në shtresat UV mund të jetë një hap i shkëlqyer drejt bërjes më miqësor ndaj mjedisit.

Si bëhet?

Veshje UV për drurin mund të bëhet në njërën nga tre mënyrat. Procesi i përgjithshëm përfshin përdorimin e një drite UV për të tharë ose forcuar veshjen. Veshjet e pastra 100 përqind do të funksionojnë në dru. Dy opsionet e tjera përfshijnë:

· Me bazë tretësi:

· Ofron më shumë rezistencë dhe ngjitje

· Ofron mbulim të shkëlqyer me trashësi minimale dhe kohë të shpejtë tharjeje

· Me bazë uji:

· Zgjedhja më e mirë për mjedisin pasi është opsion jo-toksik

· Ofron tharje të shpejtë dhe veshje më të lehtë për objekte të mëdha

· Mbulim i shkëlqyer dhe stabilitet i dritës

Koha e postimit: 25 maj 2024